- Your Price:

- $5,000.00

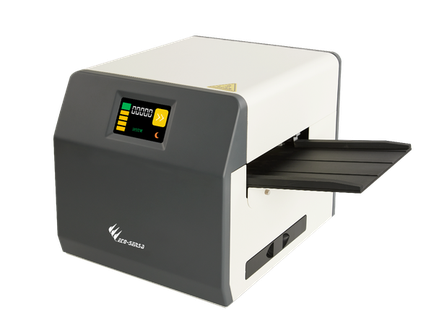

Eco-Sensa Intelligent Programmable Auto Sealer for MPN Trays

Intelligent Programmable Quantitative Sealer

The Intelligent Programmable Quantitative Sealer is a precision instrument designed to reliably seal water samples into MPN trays for microbiological analysis. Using software-controlled motors to drive heated rollers, the sealer ensures consistent sealing performance for accurate microbial testing in drinking water, surface water, and wastewater applications

Product Overview

This versatile sealer is compatible with 51-well, 97-well, and 96-well MPN trays and their respective rubber holders, making it a flexible solution for laboratories that follow GB 5750 and HJ 1001 standards. The system simplifies the process of sealing water samples into trays, improving workflow efficiency while maintaining high standards of accuracy

Key Features

-

Compatible with multiple tray formats: 51, 97, and 96 wells.

-

High-resolution touchscreen for simple, intuitive operation.

-

Automated sealing process ensures precision and efficiency.

-

Compact, durable design with a footprint suitable for bench or field use.

-

Built-in safety alerts: fault alarms, overheating warnings, and tray misalignment protection.

-

Energy-saving sleep mode reduces power consumption when idle

Technical Specifications

-

Weight: ≤ 11 kg

-

Dimensions: 394 mm (H) × 368 mm (L) × 341 mm (W)

-

Display: 4.3-inch capacitive touchscreen

-

Operating Temperature: -20 °C to room temperature

-

Power Supply: 220 V, 50 Hz, 10 A

Applications

-

Drinking water microbiology testing

-

Surface water and wastewater monitoring

-

Environmental laboratories

-

Field-based water quality sampling (vehicle-mounted capability)

Ease of Use

With a one-touch start-up, preheat indicator, and automated tray feed system, the sealer simplifies daily lab operations. Users can continuously insert multiple trays without pause, and sealed trays are dispensed smoothly at the rear of the unit. A sleep mode and clear visual indicators further streamline the workflow.

Maintenance & Support

The sealer is designed for easy cleaning and maintenance. Rubber holders are autoclavable or can be cleaned with common lab disinfectants. External surfaces and drip trays are easily accessible for routine cleaning. Internal maintenance should only be performed under engineer supervision